Description

A Light Shower Unit is light thanks to the GRP material used. The Shower unit has a door with a coverless door leaf, simple and with style! Thanks to the integrated construction, the wall of the shower unit can be used as partition. This will not only reduce weight, it will also save space and additional expenses. The surface of the inspection door and the shower unit wall has the same level, making it one cohesive component.

The Light Shower Unit

GRP CHASSIS

A GRP chassis has a high water proofness and a very low weight, limited to 60kg/m2

Upon request a floor heating system can be installed.

GRP stand for, Glass(fiber) Reinforced Plastic, this is a composite material that consists of a polymer matrix and glass fibers.

Looking for steel chassis, try the Economy shower unit.

HOISTING OF THE LIGHT SHOWER UNIT

Every Light Shower Unit (GPR) comes with clear instructions for hoisting and placement. The shower unit shall be lifted and moved to the proper position, while stability shall be maintained during the hoisting process.

The four rings on top of the wet unit must be hoisted. When less rings used to lift the wet unit mau cause tipping over or decoupling hazards.

After the unit is positioned, the rainproof cover on top of the Light Shower Unit must be removed in time to avoid a fire accident during welding and installation.

POSITIONING OF THE BATHROOM UNIT

The bottom plate of the wet unit can be adjusted in case the ground is uneven.

After adjusting the bathroom unit to the level, weld the anchor bolt to the deck.

|

Items

|

Specs

|

|---|---|

| Bottom material | Glass Reinforced Plastic (GPR) |

| Flooring finish | GPR |

| Wall material | 30/50 mm composite aluminum honeycob |

| Wall finish | PVC/PET |

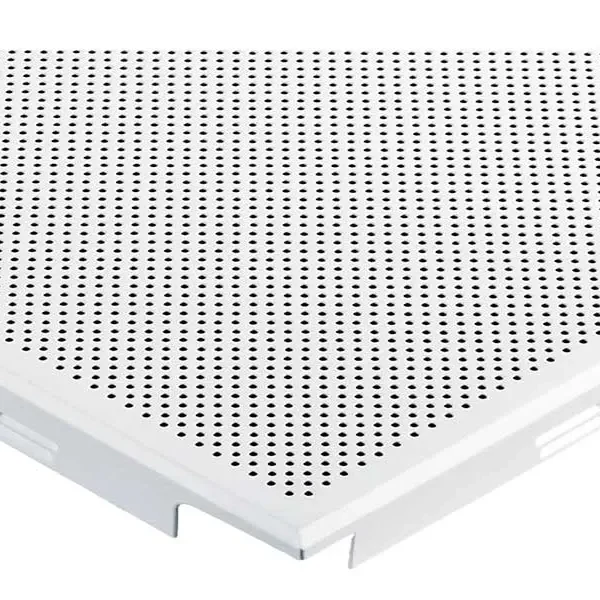

| Ceiling material | 30mm composite aluminum honeycomb panel |

| Ceiling finish | PVC |

| Door frame finish | Powder painting |

| Door leave finish | Powder painting/PVC |

| Dry wet seperation | Curtain |

| Hard – & sanitary ware | Customized |